Comprehensive monitoring for challenging environments.

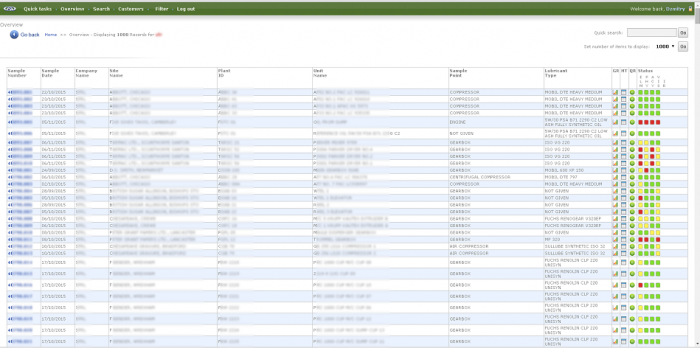

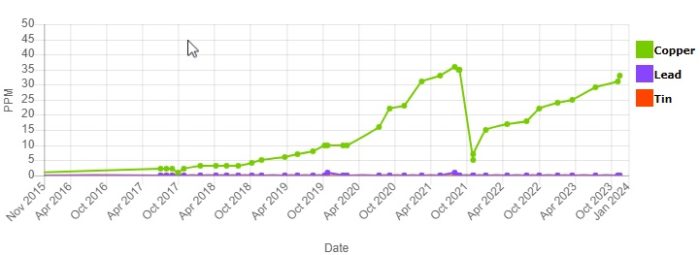

Taking a sample from a wind turbine is not the most straightforward task. The location is often remote and resources are limited. Not only will you need results you can rely on, but also maximise information from every sample by including the patch test – a window into the wear particle and contamination levels. With a simple overview of the entire wind farm you can stay informed at a glance or drill down to histories of individual units using graphical trends and patch images to identify specific issues.

Come to us for Wind Turbine Gearbox Oil Analysis, Hydraulic Oil Analysis, Main and Rotor Bearing Grease Analysis and Analytical Ferrography, and Transformer Oil Analysis.

Once you are ready to proceed please go to our Welcome page to get started or get in touch.

Viscosity is a measure of fluids resistance to flow. Often defined as an ISO or SAE viscosity grade (such as VG 220 or SAE 15W/40). Typically measured at 40 or 100ºC.

Each application will have a viscosity range suited to the task. Too high a viscosity can lead to lubricant starvation, wear in circulating pumps, increased temperatures and reduced efficiency. If viscosity is too low, the components will not be sufficiently separated resulting in excess friction and causing wear on the machinery.

A change in viscosity could be due to:

Viscosity is a measure of fluids resistance to flow. Often defined as an ISO or SAE viscosity grade (such as VG 220 or SAE 15W/40). Typically measured at 40 or 100ºC.

Each application will have a viscosity range suited to the task. Too high a viscosity can lead to lubricant starvation, wear in circulating pumps, increased temperatures and reduced efficiency. If viscosity is too low, the components will not be sufficiently separated resulting in excess friction and causing wear on the machinery.

A change in viscosity could be due to:

Oil oxidises over time and becomes more acidic indicating the age of the oil. If the oil is too acidic it can damage metal components and further accelerate the ageing process.

A rapid increase in the Acid Number may be due to:

Oil oxidises over time and becomes more acidic indicating the age of the oil. If the oil is too acidic it can damage metal components and further accelerate the ageing process.

A rapid increase in the Acid Number may be due to:

A measure of total magnetic ferrous debris in the sample irrespective of particle size.

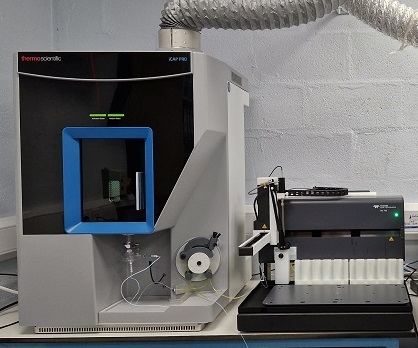

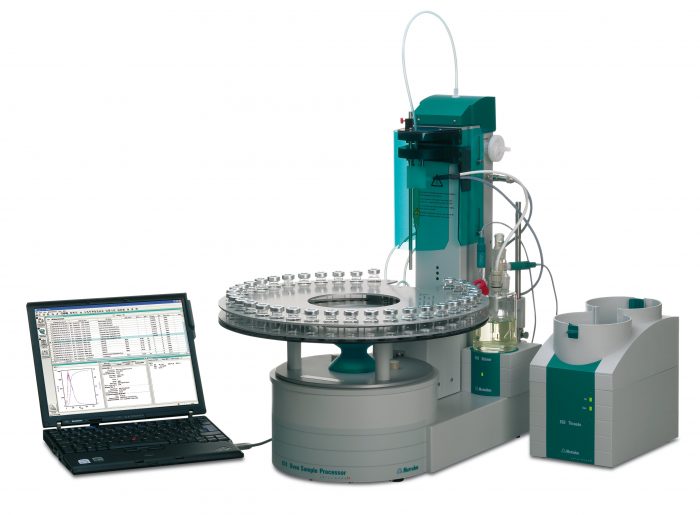

A measure of total magnetic ferrous debris in the sample irrespective of particle size. Induction Coupled Plasma Optical Emission Spectroscopy (ICP-OES) is used to measure the concentration of over 20 different elements in the oil. These include wear metals, additives and contaminants. We have recently upgraded our instrument - you can read about some of the resulting improvements

Induction Coupled Plasma Optical Emission Spectroscopy (ICP-OES) is used to measure the concentration of over 20 different elements in the oil. These include wear metals, additives and contaminants. We have recently upgraded our instrument - you can read about some of the resulting improvements

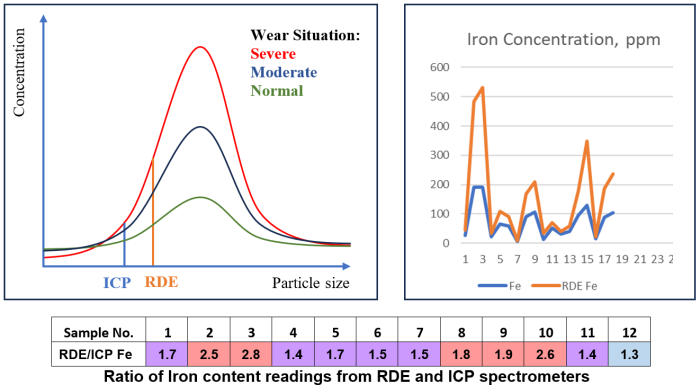

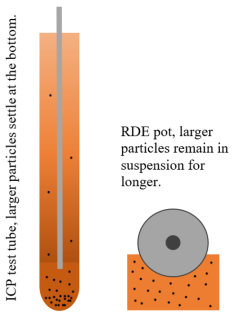

For grease and debris samples a combination of a Rotating Disk Electrode Optical Emission Spectrometer (RDE) and an ICP-OES is used. The RDE eliminates a lot of cross-contamination issues and, as no dilution with solvents is required, allows for more accurate measurement of heavily contaminated samples which would settle at the bottom of the test tube if an ICP-OES was used. The ICP-OES is then used to cover elements not measured by the RDE (mostly additives, although the wear metals are also measured). The ratio of RDE to ICP wear metal levels gives an indication of wear particle sizes.

For grease and debris samples a combination of a Rotating Disk Electrode Optical Emission Spectrometer (RDE) and an ICP-OES is used. The RDE eliminates a lot of cross-contamination issues and, as no dilution with solvents is required, allows for more accurate measurement of heavily contaminated samples which would settle at the bottom of the test tube if an ICP-OES was used. The ICP-OES is then used to cover elements not measured by the RDE (mostly additives, although the wear metals are also measured). The ratio of RDE to ICP wear metal levels gives an indication of wear particle sizes.

Excess water in the oil reduces the lubricating effectiveness by disrupting the oil film, accelerates corrosion (i.e. rusting of iron and steel surfaces), depletes and/or degrades additives and accelerates the aging (oxidation) of oil. Where large quantities of water are present oil may become emulsified. The emulsions can combine with insoluble oxidation products to form sludge which impairs the operation and reliability of equipment. In addition excessive water if present as free water can promote bacteria growth or form hard deposits on bearing surfaces.

Excess water in the oil reduces the lubricating effectiveness by disrupting the oil film, accelerates corrosion (i.e. rusting of iron and steel surfaces), depletes and/or degrades additives and accelerates the aging (oxidation) of oil. Where large quantities of water are present oil may become emulsified. The emulsions can combine with insoluble oxidation products to form sludge which impairs the operation and reliability of equipment. In addition excessive water if present as free water can promote bacteria growth or form hard deposits on bearing surfaces. Fluid cleanliness is particularly critical for hydraulic and turbine oils. High levels of particulates, especially if the particles are abrasive (e.g. silica), can increase wear of components and lead to reduced life and premature failure. It has been demonstrated that improving cleanliness by even a couple ISO Codes can lead to doubling of the expected life of a component. Conversely, contaminated lubricant will greatly reduce component lifespan and increase costs.

Fluid cleanliness is quantified by counting particles in prescribed ranges of particle sizes. It is typically expressed using an

Fluid cleanliness is particularly critical for hydraulic and turbine oils. High levels of particulates, especially if the particles are abrasive (e.g. silica), can increase wear of components and lead to reduced life and premature failure. It has been demonstrated that improving cleanliness by even a couple ISO Codes can lead to doubling of the expected life of a component. Conversely, contaminated lubricant will greatly reduce component lifespan and increase costs.

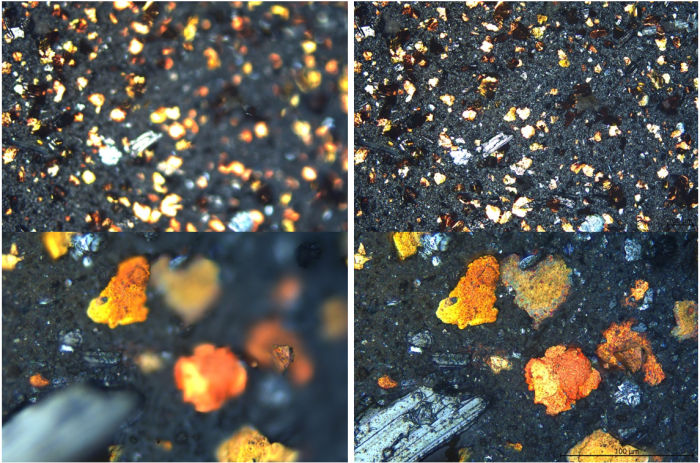

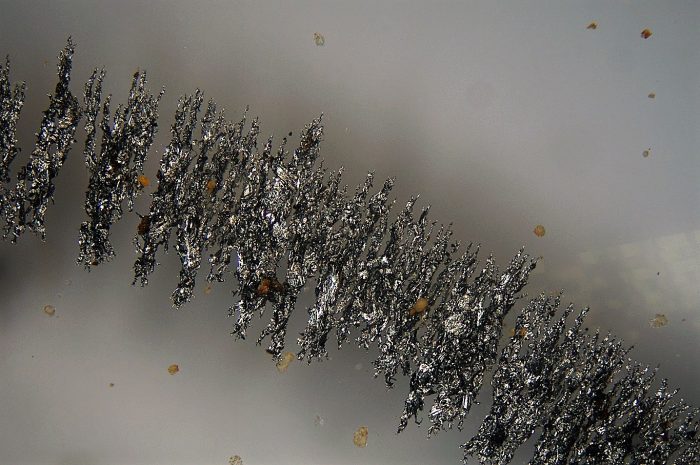

Fluid cleanliness is quantified by counting particles in prescribed ranges of particle sizes. It is typically expressed using an  We are also enjoying the Z-stack feature - it combines in-focus areas from multiple images to achieve a single fully focused composite as shown below.

We are also enjoying the Z-stack feature - it combines in-focus areas from multiple images to achieve a single fully focused composite as shown below.

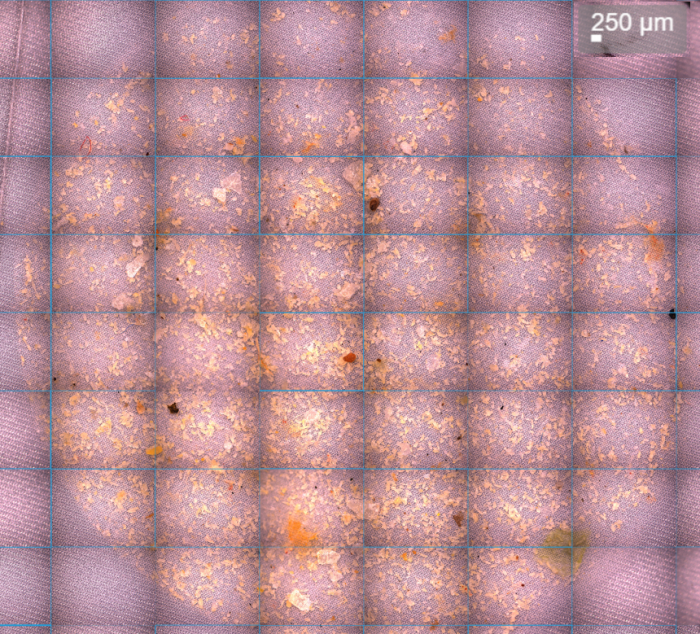

The overview/tile stitching facility lets us construct overviews of an entire membrane or

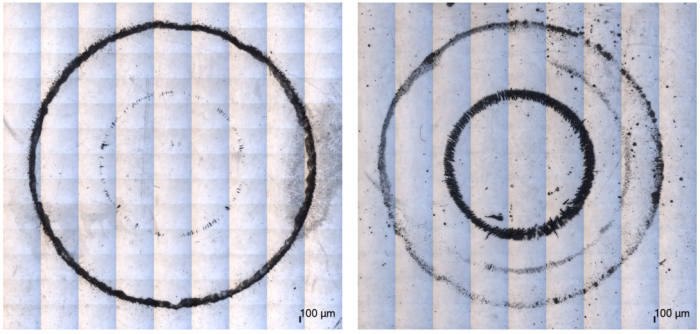

The overview/tile stitching facility lets us construct overviews of an entire membrane or  The following overviews show differences in large (inner ring) and fine (outer ring) particle densities in two ferrography samples.

The following overviews show differences in large (inner ring) and fine (outer ring) particle densities in two ferrography samples.

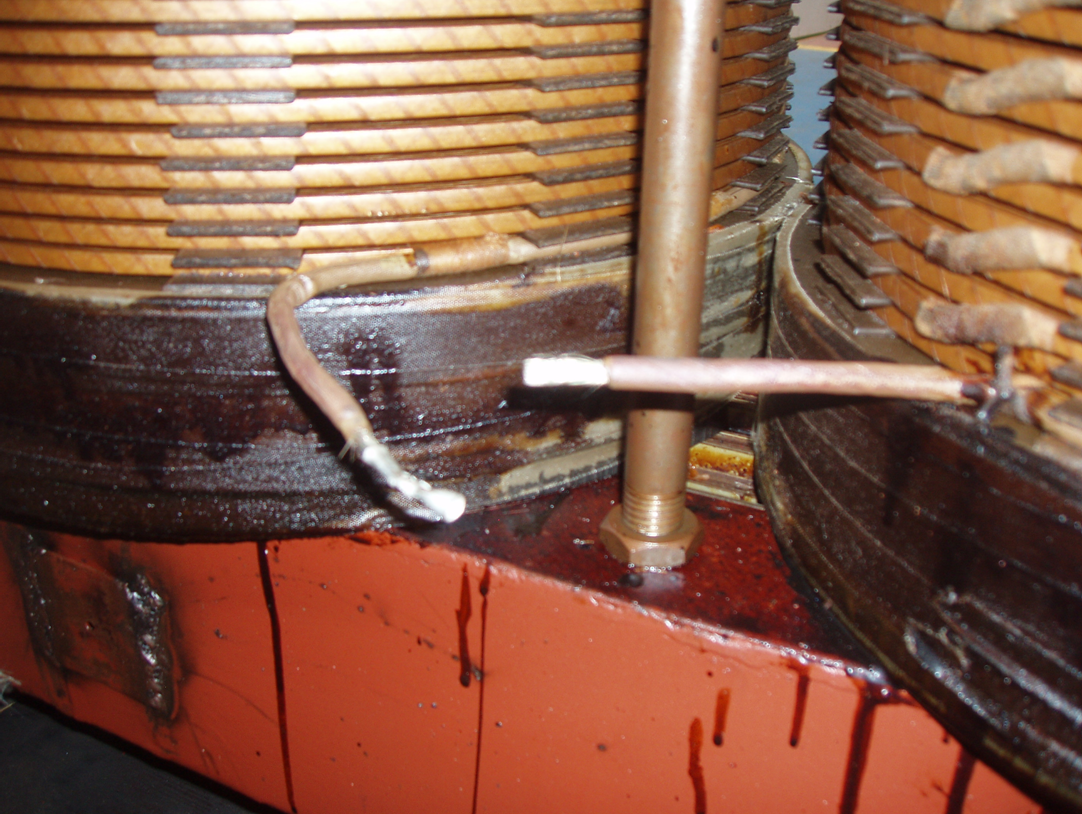

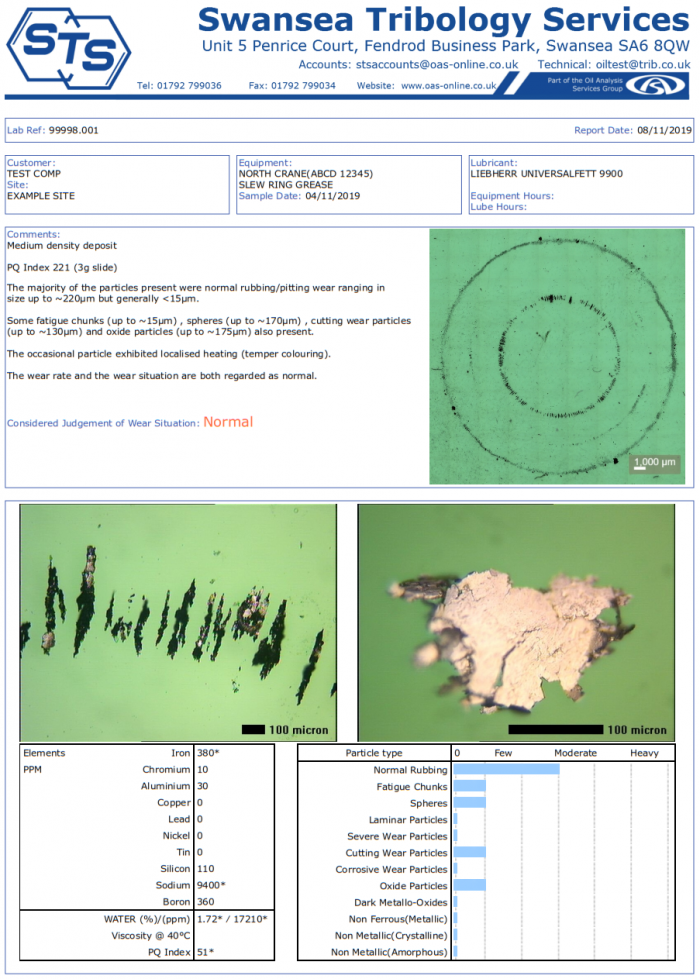

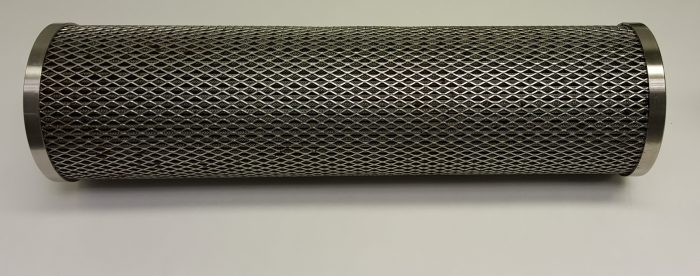

Oil filters are essential to maintaining oil cleanliness and removing wear metals and contaminants. As they perform their function, however, they also remove some of the information about wear and contamination levels from the oil stream. This is then stored in the filter itself. Fortunately Filter Debris Analysis grants us access to this store of information. By extracting and analysing the entrained particles we can learn a lot about the wear situation or the source of contamination. Oil filters come in many shapes and sizes and how we treat an individual filter will depend on its size and construction. Typically a section of the outer cage is cut out and removed to enable access to the filter media.

Oil filters are essential to maintaining oil cleanliness and removing wear metals and contaminants. As they perform their function, however, they also remove some of the information about wear and contamination levels from the oil stream. This is then stored in the filter itself. Fortunately Filter Debris Analysis grants us access to this store of information. By extracting and analysing the entrained particles we can learn a lot about the wear situation or the source of contamination. Oil filters come in many shapes and sizes and how we treat an individual filter will depend on its size and construction. Typically a section of the outer cage is cut out and removed to enable access to the filter media.

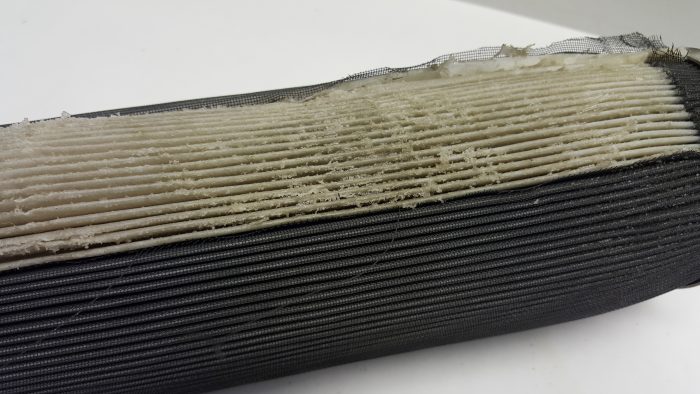

A section of the filter media is then removed and placed into a beaker. The beaker is then filled with solvent and an ultrasonic bath is used to agitate and extract the particles and any residual oil present. The solvent is then evaporated leaving the particulates and any residual oil.

A section of the filter media is then removed and placed into a beaker. The beaker is then filled with solvent and an ultrasonic bath is used to agitate and extract the particles and any residual oil present. The solvent is then evaporated leaving the particulates and any residual oil.

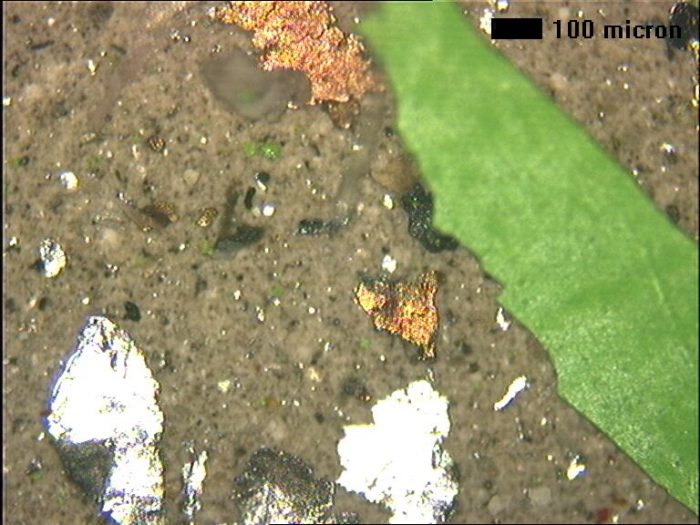

A portion of the debris is then deposited onto a filter membrane for microscopic analysis. The remaining oil/debris mixture is then analysed using a Rotating Disc Electrode Optical Emission Spectrometer to determine the elemental composition of the debris mixture. This gives a breakdown of the different wear metals and contaminants present.

Where more detail is needed, the membranes containing the particles are analysed using a Scanning Electron Microscope with Energy Dispersive X-Ray facility. This provides information on the exact elemental composition of individual particles, which can then be matched to specific component metallurgies.

A portion of the debris is then deposited onto a filter membrane for microscopic analysis. The remaining oil/debris mixture is then analysed using a Rotating Disc Electrode Optical Emission Spectrometer to determine the elemental composition of the debris mixture. This gives a breakdown of the different wear metals and contaminants present.

Where more detail is needed, the membranes containing the particles are analysed using a Scanning Electron Microscope with Energy Dispersive X-Ray facility. This provides information on the exact elemental composition of individual particles, which can then be matched to specific component metallurgies.