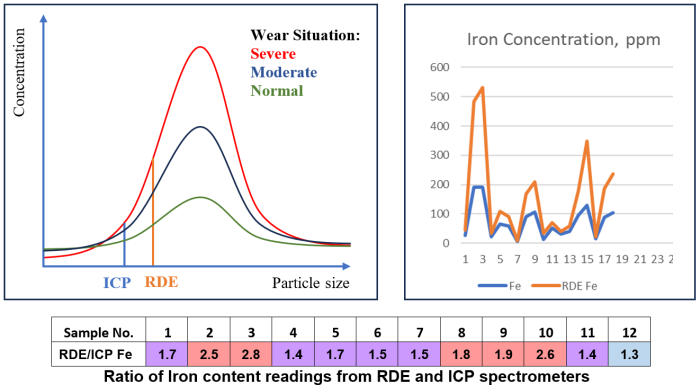

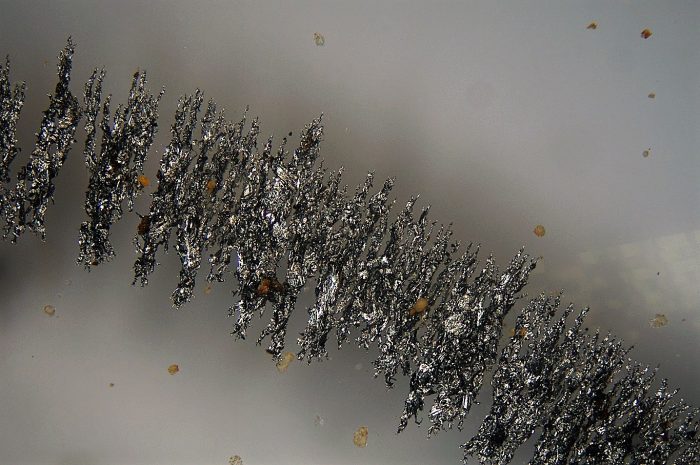

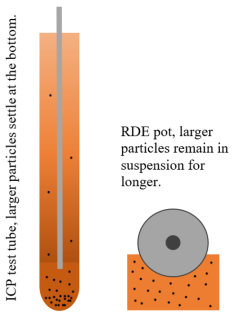

Grease analysis poses some unique challenges. Sample size is often very small yet contamination levels and particle sizes involved are often anything but! The most challenging bit is getting the sample dilute enough to pass through the fine capillaries of an ICP without clogging them up and damaging the instrument. And that’s before you start looking at the size of the debris! And the larger particles quickly settle in the low viscosity solvent mixture, avoiding detection.

Grease analysis poses some unique challenges. Sample size is often very small yet contamination levels and particle sizes involved are often anything but! The most challenging bit is getting the sample dilute enough to pass through the fine capillaries of an ICP without clogging them up and damaging the instrument. And that’s before you start looking at the size of the debris! And the larger particles quickly settle in the low viscosity solvent mixture, avoiding detection.

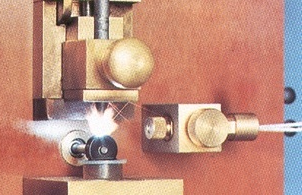

How do we manage? We use a Rotating Disk Electrode spectrometer instead*. Problem solved.

In an RDE Spectrometer the sample is picked up by a rotating disk electrode dipped into the test pot. Energy is then introduced into the system in the form of an electrical spark. Light emitted by the energised sample is collected and analysed with levels of multiple elements obtained by comparison to a calibration standard.

*We do also use the ICP to measure some of the additive elements and get the large to small ferrous debris ratio.

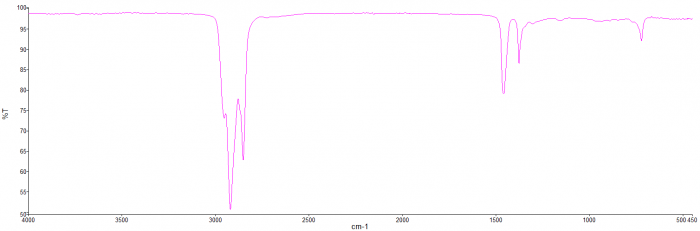

Excess water in the oil reduces the lubricating effectiveness by disrupting the oil film, accelerates corrosion (i.e. rusting of iron and steel surfaces), depletes and/or degrades additives and accelerates the aging (oxidation) of oil. Where large quantities of water are present oil may become emulsified. The emulsions can combine with insoluble oxidation products to form sludge which impairs the operation and reliability of equipment. In addition excessive water if present as free water can promote bacteria growth or form hard deposits on bearing surfaces.

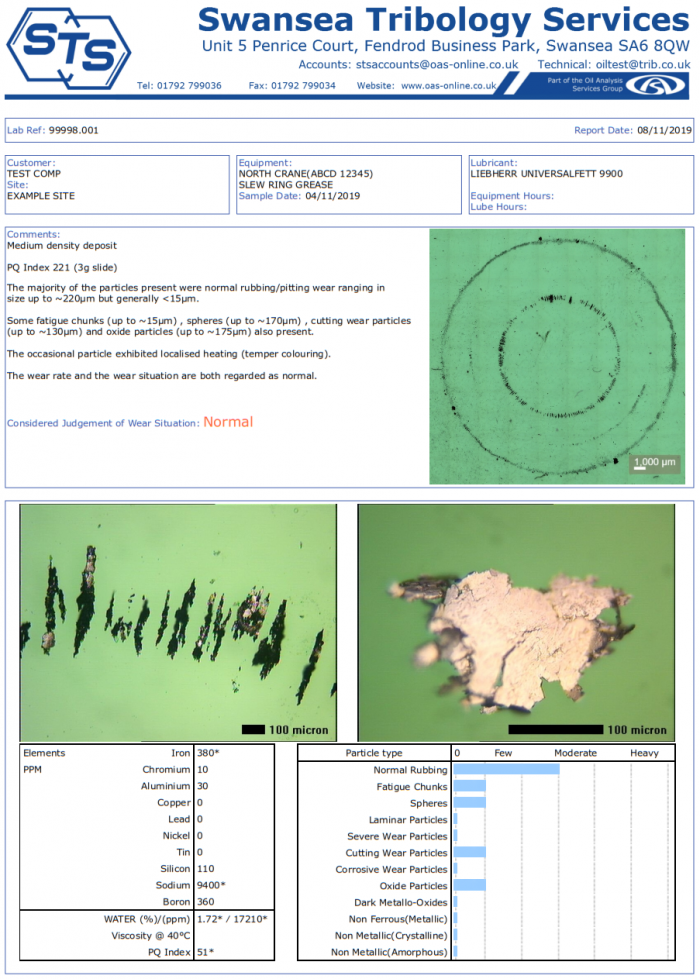

Excess water in the oil reduces the lubricating effectiveness by disrupting the oil film, accelerates corrosion (i.e. rusting of iron and steel surfaces), depletes and/or degrades additives and accelerates the aging (oxidation) of oil. Where large quantities of water are present oil may become emulsified. The emulsions can combine with insoluble oxidation products to form sludge which impairs the operation and reliability of equipment. In addition excessive water if present as free water can promote bacteria growth or form hard deposits on bearing surfaces. A measure of total magnetic ferrous debris in the sample irrespective of particle size.

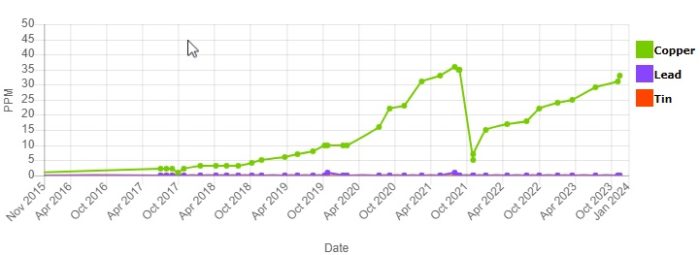

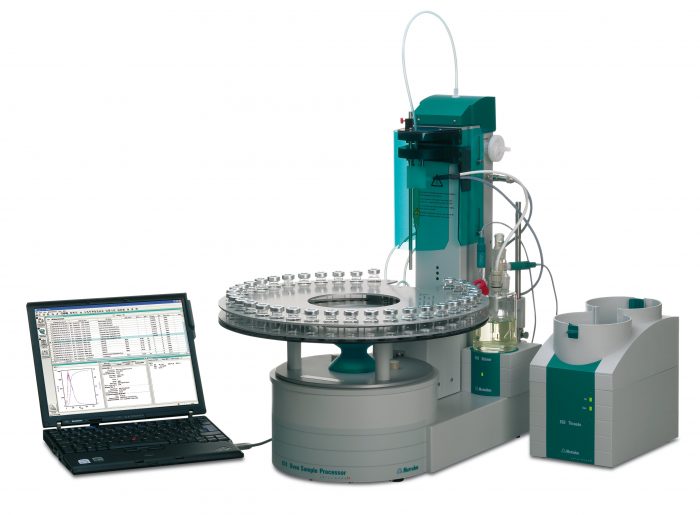

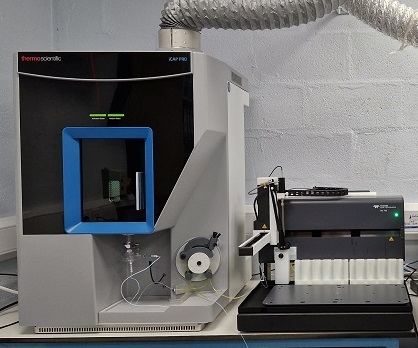

A measure of total magnetic ferrous debris in the sample irrespective of particle size. Induction Coupled Plasma Optical Emission Spectroscopy (ICP-OES) is used to measure the concentration of over 20 different elements in the oil. These include wear metals, additives and contaminants. We have recently upgraded our instrument - you can read about some of the resulting improvements

Induction Coupled Plasma Optical Emission Spectroscopy (ICP-OES) is used to measure the concentration of over 20 different elements in the oil. These include wear metals, additives and contaminants. We have recently upgraded our instrument - you can read about some of the resulting improvements