New ICP now online

Conversion of Aqueous ICP methodology to that with Internal Standard (IS).

We are introducing an improvement into the aqueous ICP analysis by adding an Internal Standard to the test method.

An Internal Standard is an additional element, that is not expected to be found in the substance being measured, which is introduced into the dilution solvent and acts as a marker to monitor how much of the sample solution makes it through the instrument. If less of the sample makes it through, the results can be factored to achieve a more accurate measurement.

We’ve used an Internal Standard in our organic methodology from the start, as lube oils come in many different formulations with vastly different viscosities. The aqueous samples have more consistent properties in some respects, however we believe that an IS will improve the precision and accuracy of measurement.

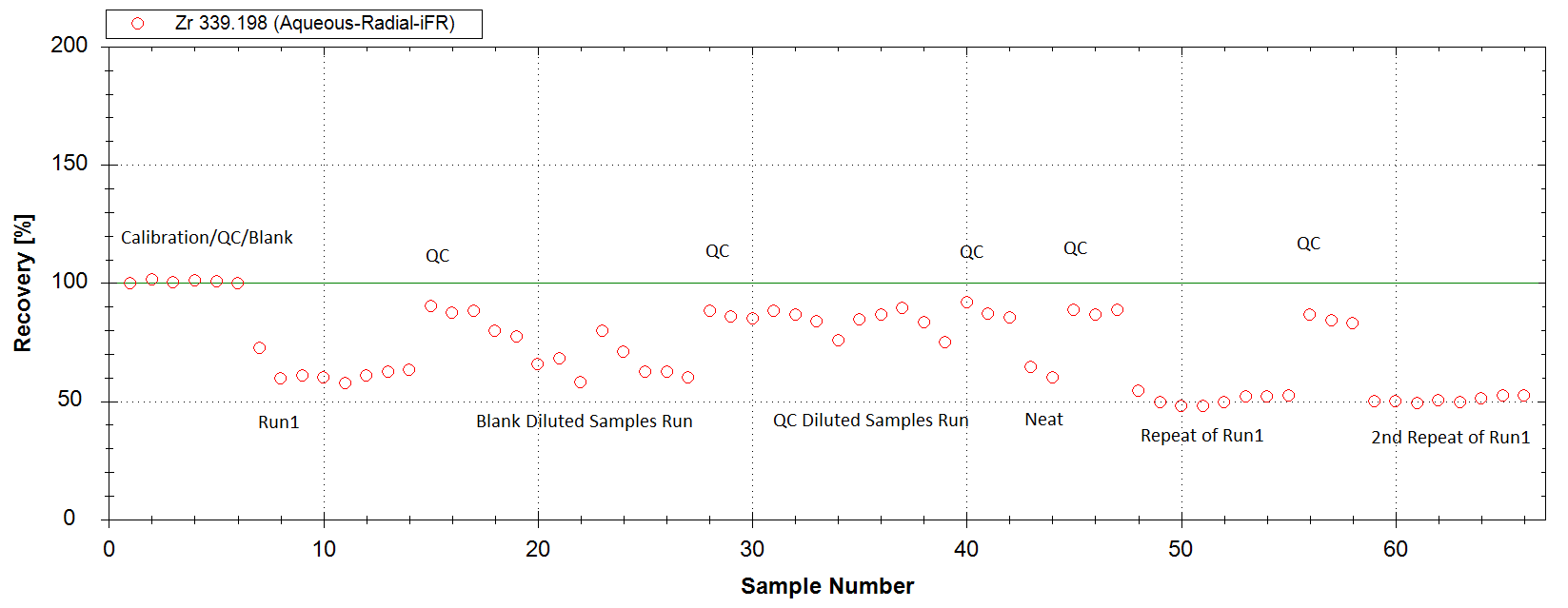

The following figure shows the recovery rate of the Zr (Zirconium) Internal Standard within a method validation run. First the Calibration Panel, the QC sample and the Blank samples were run, followed by a batch of 8 samples (Run 1), QC/Blank, a validation run of two validation samples at different levels of dilution with a blank, QC/Blank, the two validation samples diluted with the QC sample solution, QC/Blank, the two neat validation samples, QC/Blank, repeat of Run 1, QC/Blank, and a 2nd repeat of Run 1.

This validation demonstrates that some of the samples have certain properties which differ from those in the calibration and QC samples. Those could include viscosity as well as its surface tension/wetting/atomisation properties. These differences lead to a lower quantity of sample making it through the detector and can be seen having some impact on the following QC samples.

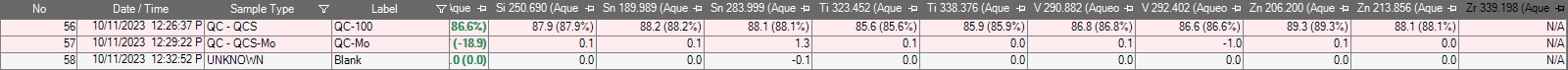

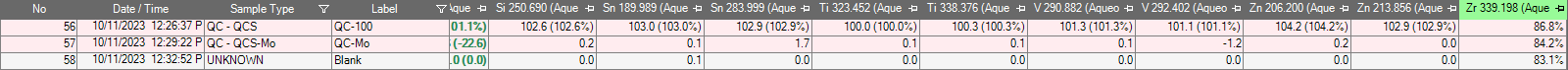

The following figures show the recovery rates of the 100ppm Quality Control sample (QC) without the Internal Standard and with the use of Internal Standard (Zr). When Zr (Zirconium) throughput is tracked and the results adjusted accordingly the QC comes out very close to the nominal value.

The extent to which elemental analysis results will be affected for specific units will depend on the specific properties of the fluid being measured. Partly on its viscosity, but also on its surface tension/wetting/atomisation properties, as mentioned above. Results for some fluids may not change at all. This is why in the initial period we intend to report both the legacy values without the use of an IS and the data with the IS enabled. This will make it possible to account for the step change and adjust the comments/action limits accordingly.

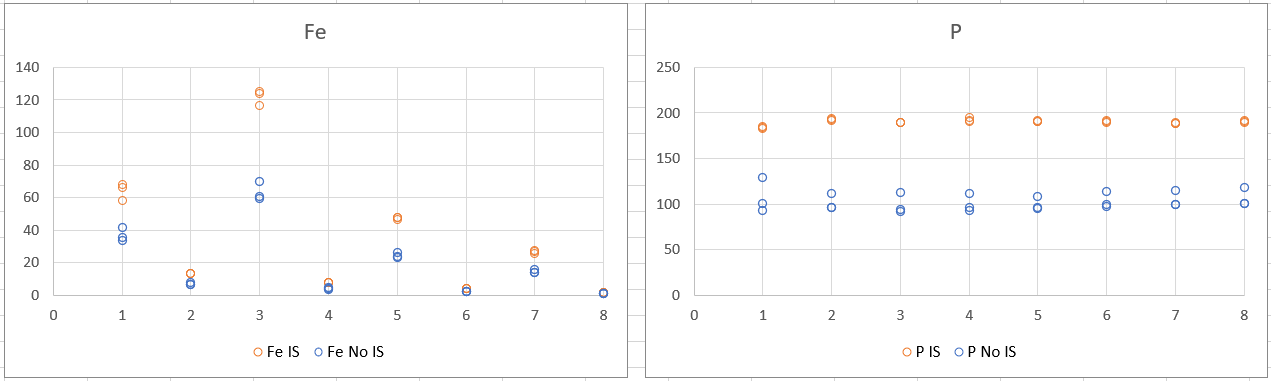

The following figures show changes to the measured values for Iron and Phosphorus across 8 samples measured in triplicate. In all cases the relative precision has been improved, although the extent of this may differ for each specific element.

Ultimately this change will lead to better accuracy, precision and improved turnaround times for the aqueous samples.

06/10/23

We have began changeover to the new Thermo iCAP Pro ICP for our elemental analysis.

The new instrument offers a wide range of improvements in sensitivity and automation. As part of the process we are also reviewing the calibration settings and the lines used and have been able to improve the linearity of the calibration and reduce the number and magnitude of any interferences. Following the switchover you may observe a slight change in the value of some of the elements at higher concentrations (e.g. additives), as the new instrument delivers better linearity. Presently we are performing analysis on both instruments and where necessary verifying the results by entering them into the system as duplicate samples. This data is not published, so should not be visible to yourselves, however you may find that the graphs reflect some of the validation measurements as duplicate values for the same date, these may be the same as the ones measured on the old system or may be slightly different.

Another big advantage of the new ICP is its ability to action repeat measurements based on data obtained for each sample. We use this to eliminate carry over from any preceeding samples. This, combined with our usual post analysis review procedures should deliver elemental data of consistently high quality.