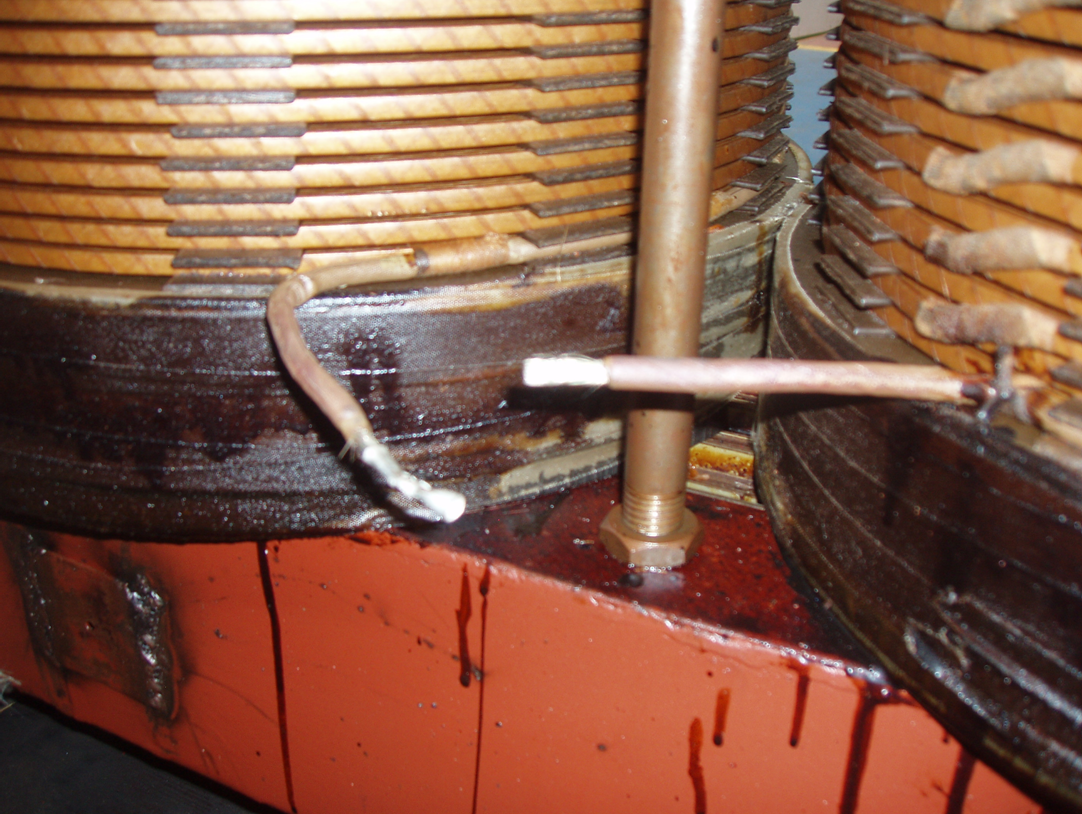

Just like lube oil analysis mentioned elsewhere a lot of value can be derived from transformer oil testing.

The tests for dissolved gases and furfuraldehyde usually indicate the condition of the transformer whilst most of the other tests e.g. acidity, electric strength, fibres reflect the quality of the oil. Since it is not desirable to have any water present, that test can also indicate whether the dryers are functioning correctly.